The industry of medical devices thrives on ingenuity. To bring new ideas into reality, you need a partner that can turn ideas into prototypes, and ultimately, production parts that are of the highest quality. Influx Labs fills this crucial position by providing a comprehensive solution to medical device manufacturers who are seeking excellence in CNC machine machining and prototype manufacturing.

From Dream to Prototype Influx Labs Facilitates Medical Device Innovation

The journey of a medical device manufacturer from the initial concept to its launch is a complex one. Influx Labs knows the importance of prototyping in this procedure. Influx Labs is a safe atmosphere for turning innovative ideas into testable prototypes. This lets you modify designs and obtain vital feedback before investing in large-scale manufacturing.

Influx Labs Expertise on CNC Machining

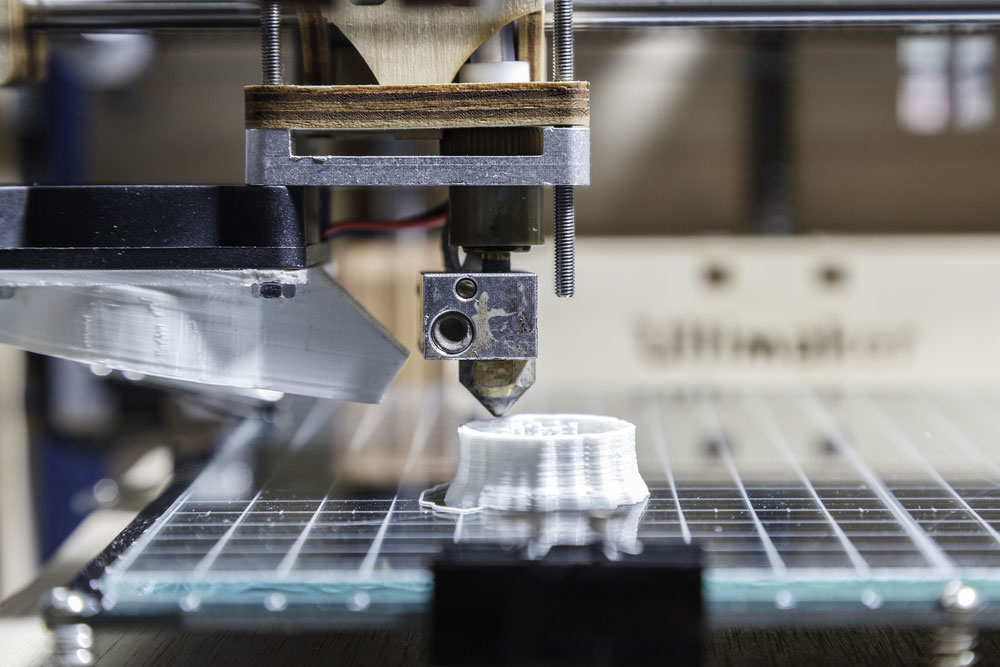

At the core of Influx Labs’ capabilities lies their cutting-edge CNC machines. CNC (Computer Numerical Control) Machining employs computer-aided commands to control precisely cutting tools, which allows the production of extremely precise and intricate parts. Influx Labs is able to make medical device prototypes as and production parts that comply with the most stringent standards for medical devices.

Beyond Prototyping: Scaling up for Production

Influx Labs’ services extend beyond the realm of rapid prototyping. They can effortlessly transition from prototyping into production at a large scale due to their knowledge of CNC cutting. This eliminates the need to locate a different manufacturing partner as well as streamlining the entire process and ensuring consistency between prototype and final product.

Certifications and traceability of materials Indefatigable commitment to quality

Influx Labs understands the importance of quality in the medical device industry. Influx Labs employs a method that ensures full material tracking throughout the entire manufacturing process. They will provide you with full transparency about the materials used to make your prototypes and parts for production. In addition, Influx Labs can provide materials and finishing certificates upon request, giving you peace of mind and meeting rigorous regulatory requirements. Get a quote at Machine Shop

Why choose Influx Labs to meet your medical device requirements?

Influx Labs is different from other prototyping firms and machining firms for several reasons. This is what makes them a great partner for medical device research:

Influx Labs is dedicated to the Medical Devices Industry. We understand the specific demands of this sector. They have the expertise and experience to manufacture top-quality medical-grade products.

Precision Engineering: Their advanced CNC capabilities allow for consistent results with unmatched precision, crucial for creating functional and durable medical devices.

Seamless transition: Influx Labs offers a one-stop shop for both prototypes and production, thus saving you time and money in finding separate vendors.

Commitment to Quality From traceability of material to certifications Influx Labs prioritizes quality control, ensuring your medical devices are in line with the highest requirements.

Influx Labs – Accelerating your Medical Device Development Journey

Influx Labs’ expertise in prototyping as well as CNC machining, helps medical device companies to bring fresh ideas to life quicker and more efficiently. Influx Labs can provide you with:

Lower Risk: Prototyping allows you to determine and resolve any potential issues early in the development phase while reducing the risk associated with production at full scale.

Faster Time to Market: Prototyping and production is streamlined with Influx Labs allows you to bring your medical device go to market faster.

Enhanced Design Refinement – Physical prototypes provide detailed testing and feedback from users that allow you to improve your designs with greater confidence.

Influx Labs can help you discover the full potential of speedy prototypes and precision CNC machines. See your innovative medical device concepts develop into reality, shaping the future of healthcare.